Weld nuts are a special sort of fastener that is used to be welded onto any other metallic object, offering a sturdy and durable fastening answer. They are to be had in numerous sizes, shapes, and configurations that lead them to be appropriate for use across several industries.

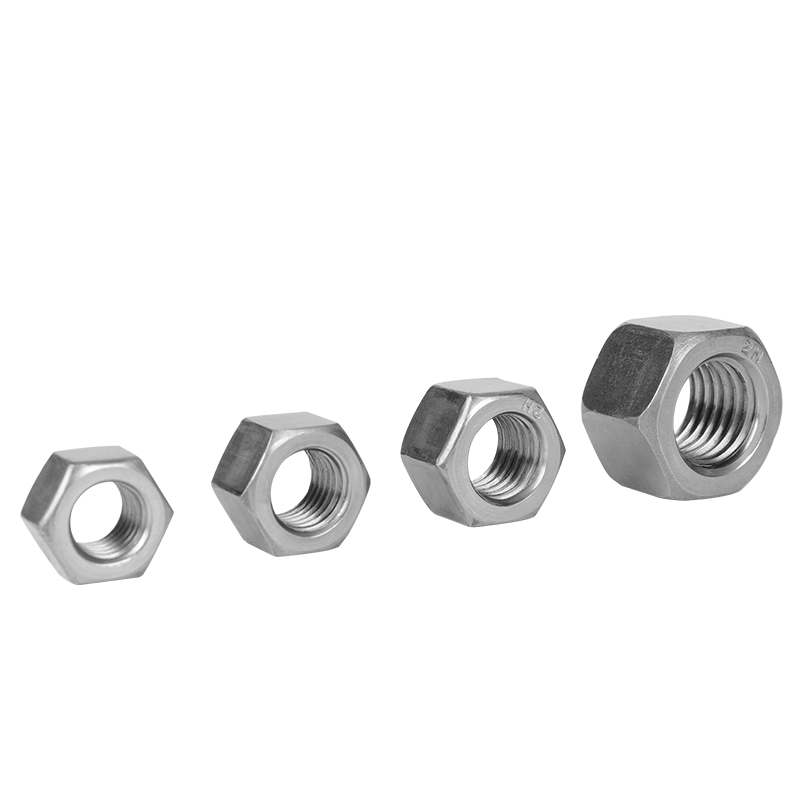

A weld nut is a steel fastener designed to be welded to a sheet of steel. It has a threaded hole that allows it to be screwed into the area after which welded to the metal. This allows it to withstand excessive masses without bending or breaking and also offers a robust, everlasting connection. Weld nuts are to be had in a variety of materials, which include carbon metallic and stainless steel. They are generally used for automobiles and other business programs.

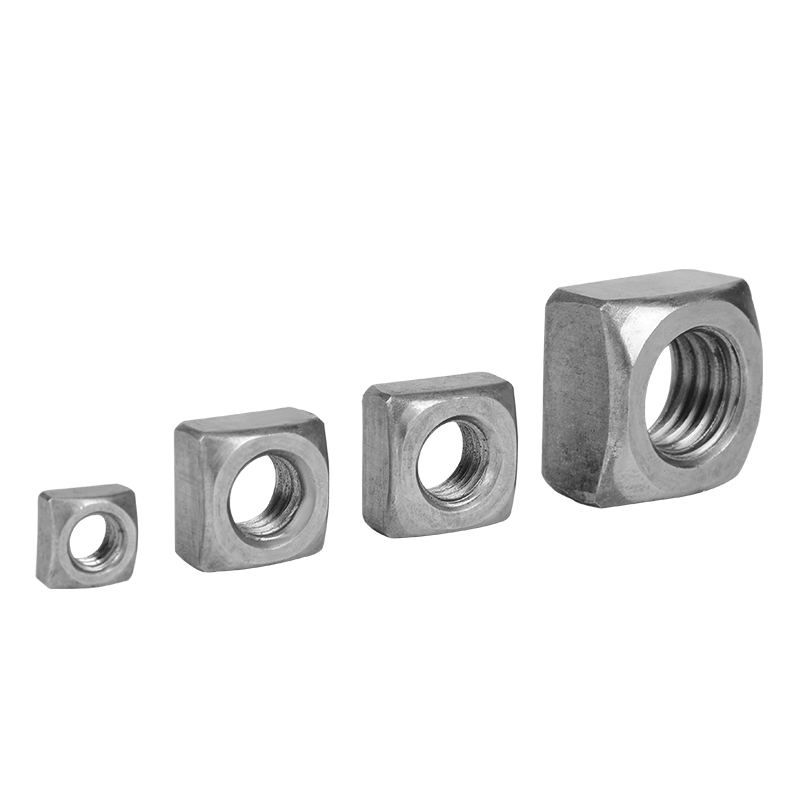

The weld nut is made from notable steel, and the projections on its floor assist in offering a sturdy and steady reference to the sheet. They also characteristic a precision pilot hollow, which facilitates ensuring that the nut is efficaciously located at the sheet. Weld nuts are to be had in various sizes, with specific projection heights and diameters to healthy the needs of the application.

To improve the performance of weld nuts, researchers have studied the impact of different nut form parameters on their projection welding behavior. An experimental design technique and electrical-thermal-mechanical FEA are used to evaluate the consequences of nut form parameters on the peak lower (test) of the weld nut leg, and on the welding time to reach 50% of the set value.

The effects of the take a look at validated that using a lower-than-everyday preliminary present-day pulse observed by a higher pulse stepped forward the test and S values of the weld nut. This development changed as a result of the reality that a bigger part of the nut frame turned into exposed to the welding beam, resulting in greater warmth loss and better penetration depths. The impact of the nut shape was greater noticeable for large-diameter weld nuts. The effect becomes not, but, found for smaller-diameter weld nuts. This result indicates that the dimensions of the nut play a bigger role inside the test and S values than do its form and the initial contemporary pulse. Therefore, the choice of a nut form and preliminary cutting-edge pulse must be taken into account for satisfactory effects.

English

English

Español

Español