In the bridge construction industry, how to ensure that

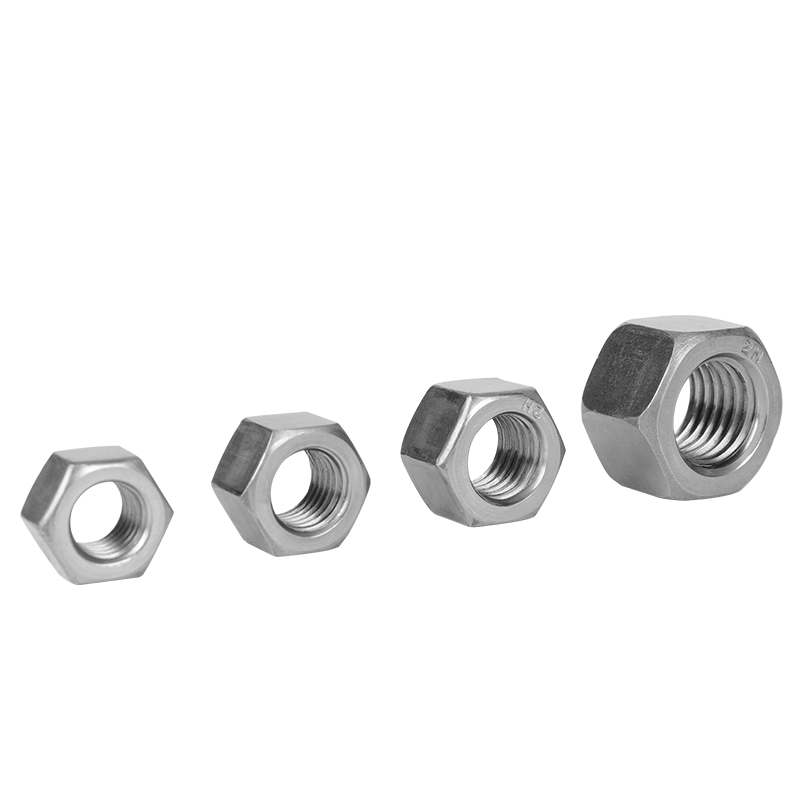

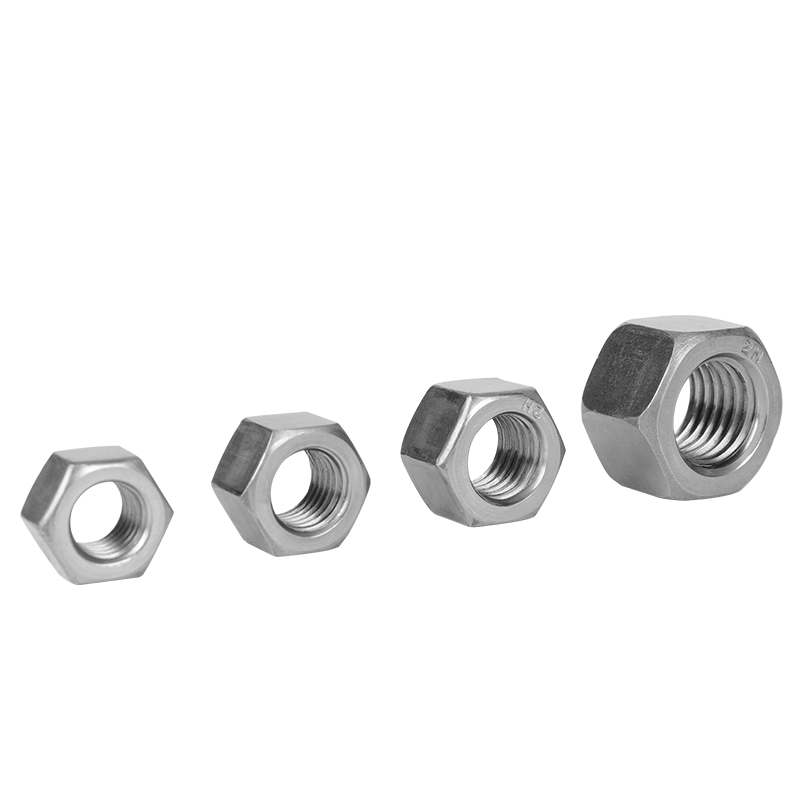

large-sized Heavy Fasteners Nuts can be installed accurately and efficiently into the bridge structure to ensure the stability and safety of the bridge?

In the bridge construction industry, ensuring that large-sized Heavy Fasteners Nuts (heavy fastener nuts) can be installed accurately and efficiently into the bridge structure is an important link in ensuring the stability and safety of the bridge. Here are the key steps and considerations to achieve this:

Precise measurement and positioning:

Use high-precision measuring tools and equipment to ensure that the installation location and dimensions of the bridge structure are accurate.

According to the bridge design drawings, accurately mark the installation position and angle of Heavy Fasteners Nuts.

Choose the right fastener:

Select Heavy Fasteners Nuts that meet the standards based on factors such as the load requirements of the bridge design, environmental conditions, and service life.

Make sure the fasteners selected have adequate strength, corrosion resistance and durability.

Use professional installation tools:

Use special installation tools that match Heavy Fasteners Nuts, such as large bolt wrenches, electric or hydraulic tightening tools, etc.

These tools provide greater torque and more even tightening force, ensuring fasteners are installed securely.

Strictly control tightening torque:

Use a torque wrench or other measuring tool to accurately control tightening torque according to the tightening torque requirements provided by the fastener manufacturer.

Avoid over-tightening or over-loosening to prevent damage or loosening of fasteners.

Inspection and preparation before installation:

Before installation, carefully check the threads and surface quality of Heavy Fasteners Nuts and bolts to ensure there is no damage, rust or other defects.

Clean the oil dirt, impurities, etc. on the surface of the mounting holes and threads to ensure that the fasteners can be installed smoothly and achieve the expected fastening effect.

Monitoring and recording during installation:

During the installation process, the installation status of each fastener is monitored in real time to ensure that the installation quality meets the requirements.

Record key information such as the installation position and tightening torque of each fastener for subsequent inspection and traceability.

Post-installation inspection and testing:

After installation is complete, conduct a thorough inspection of the bridge structure to ensure that all Heavy Fasteners Nuts have been installed and tightened correctly.

Conduct necessary load tests and vibration tests to verify the stability and safety of the bridge structure.

Regular maintenance and inspection:

During the use of the bridge, the fasteners should be inspected and maintained regularly to ensure that they remain in good working condition.

Deal with problems such as loosening and damage of fasteners discovered in a timely manner to prevent them from affecting the stability and safety of the bridge.

Training and technical support:

Provide professional training to installation workers to ensure they master correct installation methods and techniques.

Provide necessary technical support and problem resolution to deal with various problems and challenges that may arise during the installation process.

By following the above steps and considerations, you can ensure that large-sized Heavy Fasteners Nuts can be installed accurately and efficiently into the bridge structure, thereby ensuring the stability and safety of the bridge.

ASTMA194/A563 Carbon Steel Heavy Duty Nuts

ASTMA194/A563 Carbon Steel Heavy Duty Nuts