In the context of automotive manufacturing, how do surface treatments on Square Nuts, such as chromate conversion coating, affect their corrosion resistance and durability? How to ensure that Square Nuts can maintain its fastening performance for a long time in harsh driving environments?

In the field of automotive manufacturing, surface treatments such as chromate conversion coating on Square Nuts have a significant impact on their corrosion resistance and durability. Here is a detailed analysis of its impact:

Effect of chromate conversion coating on corrosion resistance:

The chromate conversion coating can form a dense protective film on the surface of Square Nuts. This film can effectively isolate the Square Nuts from contact with corrosive media (such as moisture, oxygen, acidic or alkaline substances), thus significantly improving the performance of Square Nuts. Nuts corrosion resistance.

Chromate conversion coatings generally have good adhesion and weather resistance, maintaining their stability and effectiveness under harsh environmental conditions, thus protecting Square Nuts from corrosion over the long term.

Effect of Chromate Conversion Coating on Durability:

Chromate conversion coating not only improves the corrosion resistance of Square Nuts, but also improves its wear resistance and fatigue resistance to a certain extent, thereby extending the service life of Square Nuts.

The durability of Square Nuts can be further improved by optimizing the preparation process and parameters of the chromate conversion coating. For example, controlling the content and proportion of each component in the plating solution, adjusting the temperature and pH value of the plating solution, etc., can have a positive impact on the performance of the coating.

In harsh driving environments, to ensure that Square Nuts can maintain its fastening performance for a long time, the following measures can be taken:

Choose high-quality Square Nuts and bolt fasteners to ensure they have sufficient strength and durability.

Apply appropriate chromate conversion coating or other effective anti-corrosion coating to the surface of Square Nuts to improve its corrosion resistance and durability.

During the assembly process, the torque management of bolt fasteners is strictly controlled to ensure a tight fit and solid connection between Square Nuts and connecting parts. This can be achieved through the use of intelligent torque management systems that are able to pre-set process requirements and monitor operating results in real time.

Inspect and maintain Square Nuts regularly to detect and deal with possible loosening, corrosion or damage issues in a timely manner. This can be accomplished by regularly tightening bolts, removing corrosion products, and replacing damaged fasteners.

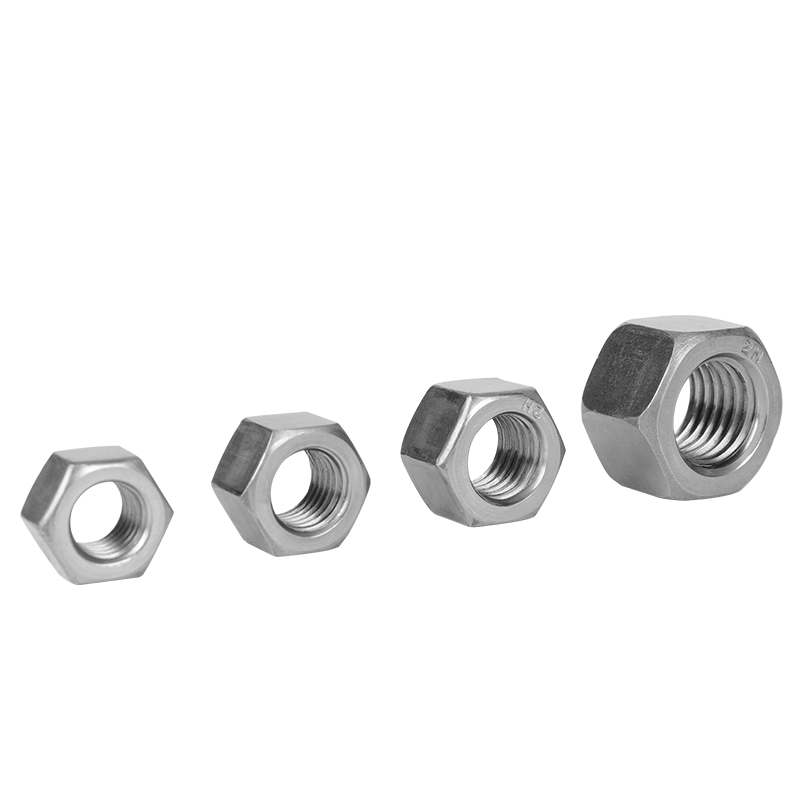

M5-M10 DIN Thin Carbon Steel/stainless steel Square Nut

English

English

Español

Español