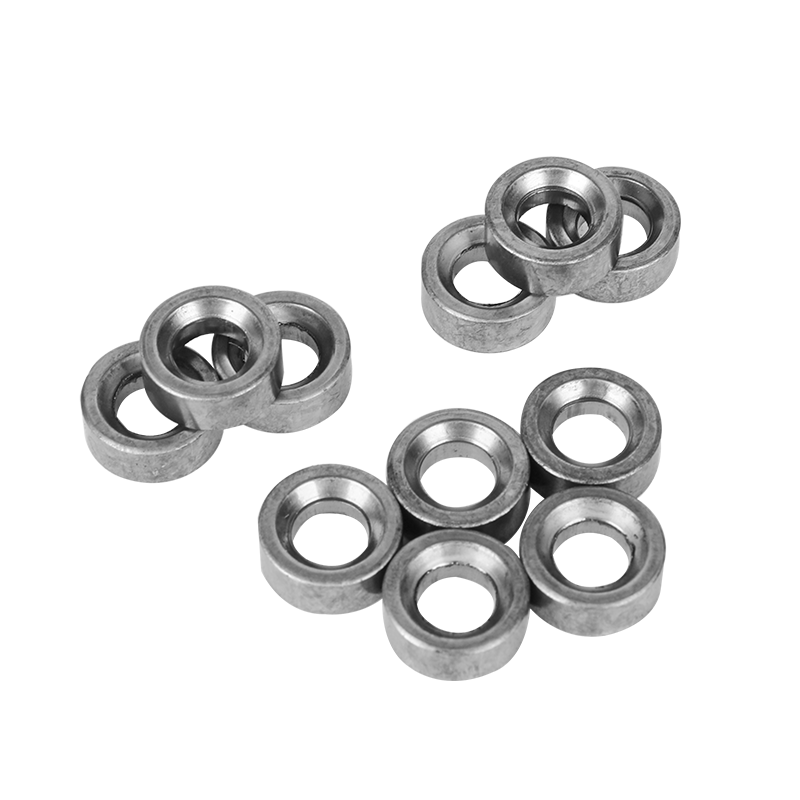

1. Understanding Round Carbon Steel Kick Shaft Bushings

A Round Carbon Steel Kick Shaft Bushing is a cylindrical component made of carbon steel that fits into a shaft system. It is used to reduce friction between moving parts, provide alignment, and absorb the wear and tear that occurs over time in mechanical systems. The "kick shaft" refers to a type of shaft that is typically subjected to repeated oscillation or rotational movements, while the carbon steel construction ensures the bushing is strong and durable.

2. How Carbon Steel Contributes to Durability

The material of a bushing plays a crucial role in its ability to withstand stress and perform optimally over time. Carbon steel, an alloy of iron and carbon, offers several advantages that contribute to the enhanced durability of these bushings:

High Tensile Strength: Carbon steel is known for its strength and ability to resist deformation under heavy loads. This is critical for bushings used in high-load applications like machinery, where parts need to remain intact despite continuous motion.

Impact Resistance: The tough nature of carbon steel allows the bushing to absorb impacts without cracking or breaking, which is essential in environments where machinery faces constant shock or vibration.

Corrosion Resistance: When properly treated, carbon steel bushings can resist rust and corrosion, extending their lifespan even in harsh environmental conditions.

3. Minimizing Wear in Moving Parts

The primary function of a bushing is to reduce wear between two moving parts. By fitting into a shaft system, the Round Carbon Steel Kick Shaft Bushing serves as a buffer that prevents direct contact between the shaft and other components. Here's how it minimizes wear:

Friction Reduction: Bushings reduce friction between the moving parts they separate, which minimizes the abrasive forces that cause wear. The smoother the movement, the less the risk of surface degradation.

Load Distribution: Bushings help distribute the load across the surface area more evenly, preventing localized stress points that can cause significant wear in specific areas.

Shock Absorption: The bushing acts as a shock absorber, reducing the force transferred to the shaft and other parts. This is especially beneficial in high-impact machinery, where constant vibrations and shocks can lead to rapid wear.

4. Enhancing Machine Performance

Durability and reduced wear are not only about protecting individual components; they also contribute to the overall performance of the machine. Here’s how Round Carbon Steel Kick Shaft Bushings contribute to better machine performance:

Improved Efficiency: By reducing friction and wear, these bushings help machinery run more efficiently. With less resistance between moving parts, energy is not wasted on unnecessary friction, which translates into lower operating costs and more effective machinery.

Longer Service Life: The enhanced durability provided by carbon steel bushings means that machines require less frequent maintenance or part replacements, leading to fewer downtimes and a longer service life.

Consistency: The stable performance of these bushings ensures that machinery continues to operate smoothly without sudden performance drops due to worn parts, which can compromise precision and functionality.

5. Cost-Effective Solution

Investing in Round Carbon Steel Kick Shaft Bushings can provide significant cost savings in the long run. Here's why:

Reduced Maintenance: With wear and tear minimized, the need for frequent repairs or part replacements is reduced, cutting down on maintenance costs.

Increased Uptime: Because the bushings reduce friction and wear, machinery operates more reliably, resulting in less downtime for repairs and maintenance.

Extended Component Lifespan: By enhancing the durability of both the bushing and the components it protects, these bushings contribute to the overall longevity of the machine, making them a wise investment for industries looking to reduce costs over time.

6. Applications of Round Carbon Steel Kick Shaft Bushings

Round Carbon Steel Kick Shaft Bushings are widely used in industries that rely on heavy machinery, where durability and wear resistance are essential. Some common applications include:

Automotive Industry: In automotive systems such as suspension components and steering mechanisms, bushings help reduce friction and wear, contributing to smoother handling and longer vehicle life.

Construction Equipment: Heavy equipment used in construction, like cranes, bulldozers, and excavators, experiences significant stress, making high-quality bushings crucial to preventing damage and ensuring smooth operation.

Industrial Machinery: In factories and manufacturing plants, machinery like presses, conveyors, and mixers all rely on bushings to maintain performance and durability, especially under high load and vibration conditions.

Agricultural Equipment: Tractors, harvesters, and other farming machinery are subjected to constant motion and impact. Carbon steel bushings help reduce wear and tear, ensuring the equipment operates effectively for longer periods.

English

English

Español

Español