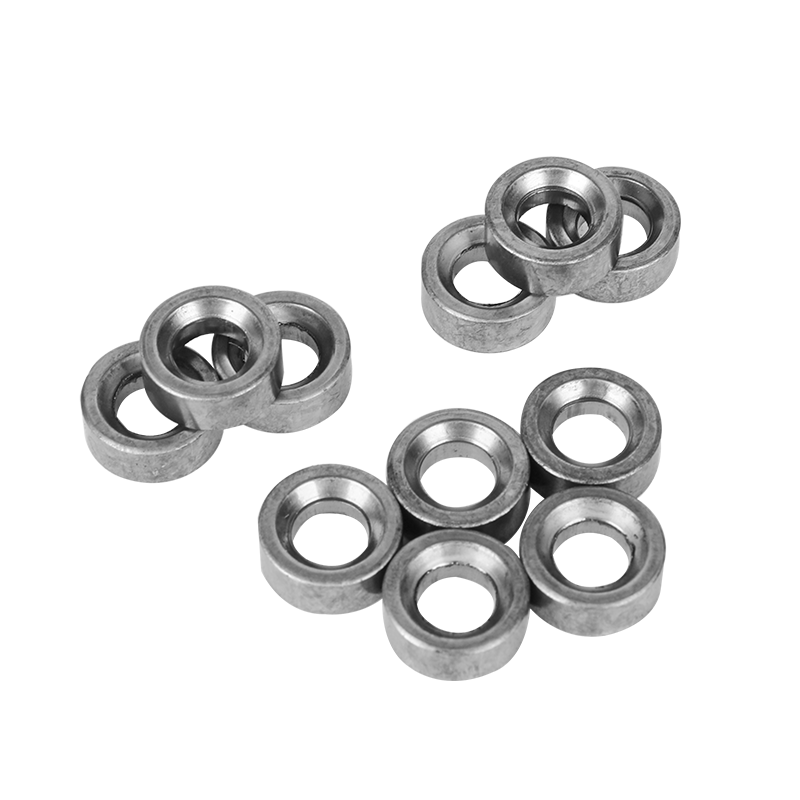

Metal strapping buckles are used to fasten strapping around goods, creating a secure bond that helps in stabilizing the load. They are often paired with polypropylene, polyester, or steel strapping and come in various shapes and sizes to fit different types of applications. These buckles work by threading the strapping through the buckle and then tightening it to hold the strap in place. Once the strap is secured, the buckle is used to clamp the strapping, creating a tight, durable hold that prevents any movement during transport.

Benefits of Metal Strapping Buckles

Strength and Durability: Metal strapping buckles are designed for strength and longevity. They are often made of high-quality steel or stainless steel, which can withstand the stresses of transportation and the elements. This ensures that goods are tightly secured and protected from damage, even during long-distance shipping or rough handling.

Versatility: These buckles can be used for a wide range of applications, from securing pallets of goods to bundling heavy construction materials. Whether in the logistics, agriculture, or manufacturing industries, metal strapping buckles are adaptable and versatile for a variety of load types and shipping environments.

Cost-Effective: While the initial investment in metal strapping equipment may be higher than alternatives, the long-term benefits of using metal buckles far outweigh the costs. They have a longer lifespan and require less maintenance, making them a cost-effective solution for businesses that need reliable, long-term strapping.

Corrosion Resistance: Stainless steel buckles, in particular, offer excellent resistance to corrosion, making them ideal for industries that deal with harsh environments, such as marine transport or outdoor storage. The durability against rust and corrosion ensures that your strapping remains secure, even under challenging conditions.

How to Use Metal Strapping Buckles Effectively

Proper use of metal strapping buckles is essential for ensuring maximum security of the load. Here are some steps for using metal strapping buckles effectively:

Select the Right Strapping: Choose the correct type and size of metal strapping that matches the weight and nature of the load. The strapping material should be strong enough to withstand the tension required to secure the goods properly.

Thread the Strap through the Buckle: Pass the loose end of the strapping through the buckle, ensuring the strap is positioned properly. Tighten the strap around the load to ensure a firm hold.

Use a Tensioner: A tensioning tool should be used to tighten the strap around the load. This tool will help achieve the necessary tension to secure the buckle and strapping in place.

Clamp the Buckle: Once the strapping is tightened, use the buckle to clamp the strap in place. This will lock the strap into position, ensuring that the goods are securely fastened.

Seal the Strap: For added security, a metal seal can be used along with the buckle to ensure that the strap remains locked in place throughout the journey.

Trends in the Metal Strapping Industry

With the growth of global trade and the increasing demand for more secure, efficient, and cost-effective packaging solutions, the use of metal strapping and buckles has seen significant advancements. Here are some key trends in the industry:

Increased Automation: As companies seek greater efficiency in packaging and shipping, there has been a move towards automated strapping machines. These machines can automatically feed and tighten straps, applying the metal buckles in a fraction of the time it would take manually, enhancing productivity.

Eco-friendly Materials: Sustainability is becoming a more significant concern in all industries, and metal strapping buckles are no exception. Companies are exploring more environmentally friendly materials that reduce the carbon footprint of manufacturing and improve recycling efforts.

Custom Solutions: With the diverse range of industries using metal strapping buckles, many manufacturers are offering customized solutions tailored to specific needs. Whether it's unique sizes, corrosion-resistant finishes, or high-strength materials, the ability to tailor products to specific applications is helping businesses streamline their packaging processes.

Integration with IoT (Internet of Things): The integration of smart technology into strapping equipment is on the rise. IoT-enabled systems are being used to track the status of strapping, monitor the quality of the fastenings, and even alert businesses when a buckle or strap may need maintenance, further enhancing reliability and minimizing downtime.

English

English

Español

Español