In the heavy machinery manufacturing industry, large-sized Heavy Fasteners Nuts often need to withstand huge torque and shear forces. What are the special requirements for these nuts in design and material selection?

In the heavy machinery manufacturing industry, large-sized Heavy Fasteners Nuts (heavy fastener nuts) often need to withstand huge torque and shear forces, so their design and material selection have special requirements. The following is a detailed analysis of these special requirements:

Design requirements

High-strength design: The design of the nut needs to ensure that the structural integrity and stability can be maintained when subjected to high torque and shear forces. This usually involves increasing the thickness of the nut, using reinforcing ribs, or optimizing the thread design.

High-precision fit: The fit between the nut and the bolt needs to be very precise to ensure that there is no excessive stress concentration or fit failure when subjected to high torque. This requires the internal thread of the nut to have high precision and consistency.

Anti-loosening design: In order to prevent the nut from loosening under high vibration or impact conditions, special anti-loosening designs are required, such as locking threads and using locking washers.

Material selection

High-strength materials: Nuts need to be made of high-strength materials, such as high-strength alloy steel, stainless steel, etc., to ensure that they can withstand huge torque and shear forces. These materials usually have high yield strength and tensile strength.

Good wear resistance and corrosion resistance: Since nuts are often used in conjunction with fasteners such as bolts, they need to have good wear resistance to extend their service life. At the same time, nuts working in humid or corrosive environments also need to have good corrosion resistance.

Heat treatability: Some materials can be heat treated to improve their mechanical properties and corrosion resistance. Therefore, heat treatability needs to be considered when selecting materials so that the performance of the nuts can be further optimized through heat treatment.

Example numbers and information

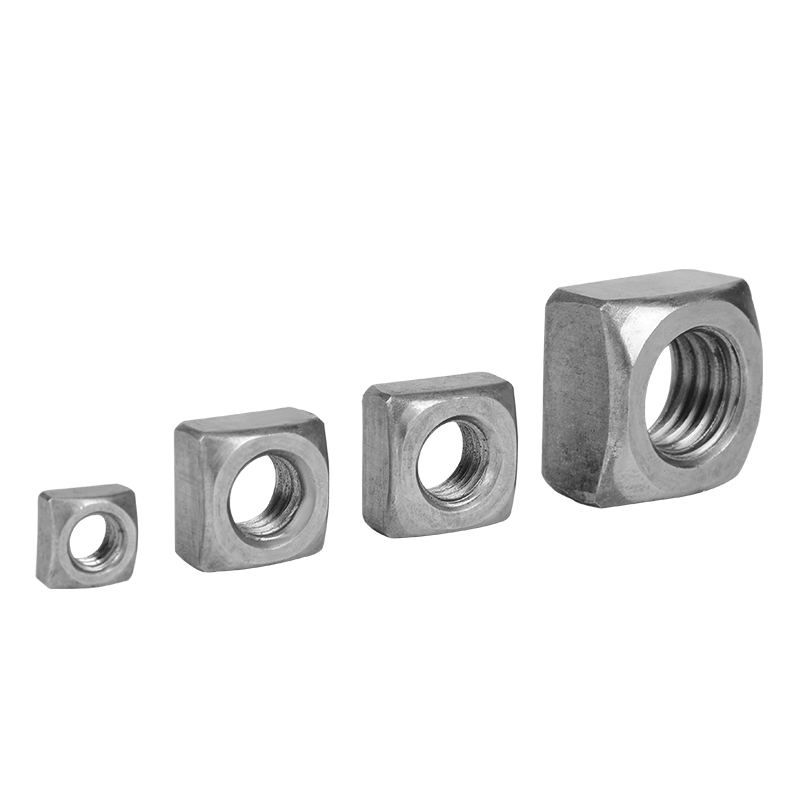

Specification range: The specifications of heavy-duty fastener nuts can range from M3 to M30 (nut diameter), which indicates that they are suitable for application scenarios of different sizes and loads.

Material selection: Nuts can be divided into several types such as carbon steel, high strength, stainless steel, and plastic steel according to different materials. In the heavy machinery manufacturing industry, high strength and stainless steel are usually the preferred materials.

Product standards: The design and production of nuts need to follow the corresponding national and international standards, such as ANSI, DIN, JIS, BS, GB and ISO. These standards specify the requirements for the size, tolerance, material properties, etc. of nuts.

In the heavy machinery manufacturing industry, large-sized Heavy Fasteners Nuts need to withstand huge torque and shear force. In order to meet these requirements, the nuts need to have high strength, high-precision matching, anti-loosening design and other characteristics in design and material selection, and be manufactured with high-strength, wear-resistant and corrosion-resistant materials. At the same time, it is also necessary to follow the corresponding national and international standards for production and inspection.

ASTMA194/A563 Carbon Steel Heavy Duty Nuts

English

English

Español

Español