The primary differences between hex nut styles 1 and 2 are based on their dimensions and applications. Here are the key distinctions:

Dimensions and Size:

Style 1 Hex Nuts: These are standard hex nuts and have a greater width across flats. They are the most commonly used hex nuts and have a higher profile and more metal, which provides a greater bearing surface for the wrench.

Style 2 Hex Nuts: These are smaller and thinner than style 1 hex nuts. They have a reduced width across flats, which makes them lighter and allows for a more compact design.

Applications:

Style 1 Hex Nuts: Due to their larger size and higher profile, style 1 hex nuts are typically used in applications requiring higher torque and greater strength.

Style 2 Hex Nuts: These are used in applications where space is limited, and a lower profile is needed. They are suitable for light-duty applications where the load requirements are not as high as those for style 1 hex nuts.

Standards and Specifications:

Style 1 and Style 2 hex nuts are specified differently in various standards such as the ISO, ANSI, and DIN. These standards define the dimensions, tolerances, and mechanical properties of each style.

Bearing Surface:

Style 1 Hex Nuts: The greater bearing surface provides better load distribution, which is advantageous for high-load applications.

Style 2 Hex Nuts: The reduced bearing surface is adequate for lower-load applications but may not provide the same level of load distribution as style 1 hex nuts.

The choice between style 1 and style 2 hex nuts depends on the specific requirements of the application, including the available space, load capacity, and torque requirements. Style 1 hex nuts are preferred for heavy-duty applications, while style 2 hex nuts are suited for lighter-duty and space-constrained applications.

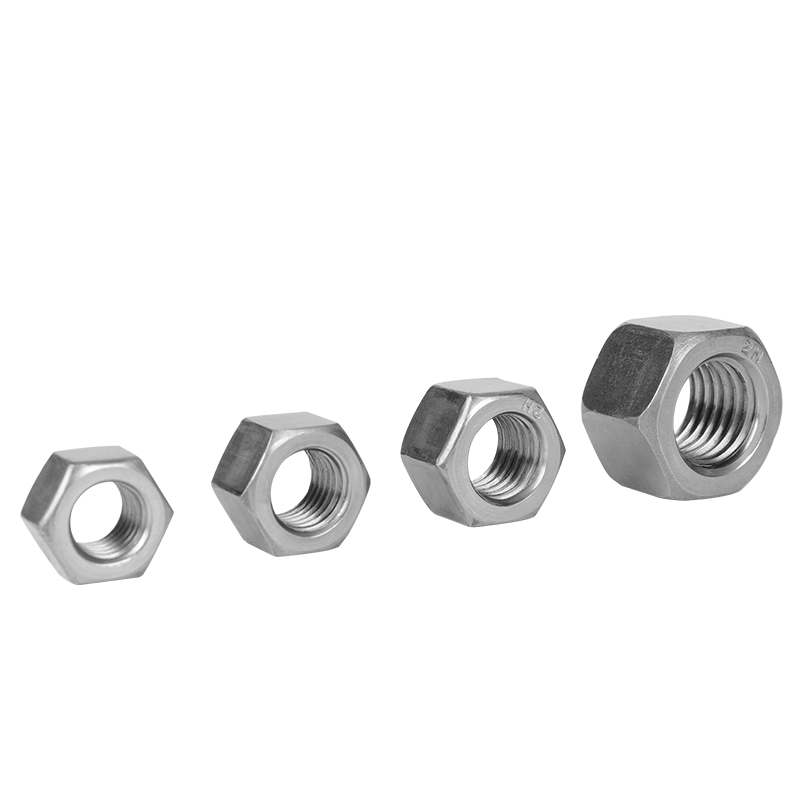

#6-3/8 M5-M36 Single Chamfered Hexagon Nuts

English

English

Español

Español