In various industrial projects and machinery manufacturing, Heavy Fasteners Nuts play a key role in connection and tightening, and their quality is directly related to the stability and safety of the overall structure. Therefore, mastering the correct purchase points is the key to ensuring the purchase of high-quality products.

1. Clarify the use requirements and specifications

Different application scenarios have different requirements for Heavy Fasteners Nuts. In the construction field, nuts used for connecting large steel beams need to withstand huge shear and tension forces, and must have high strength and high toughness; while in chemical equipment, nuts must have good corrosion resistance to cope with complex chemical erosion. Therefore, before purchasing, it is necessary to clarify the key specifications and parameters of the required nuts, such as size, strength grade, and material properties, based on the specific use scenario. For example, if it is used for oil drilling platforms, nuts that meet API (American Petroleum Institute) standards and have resistance to hydrogen sulfide corrosion should be selected.

2. Pay attention to material quality

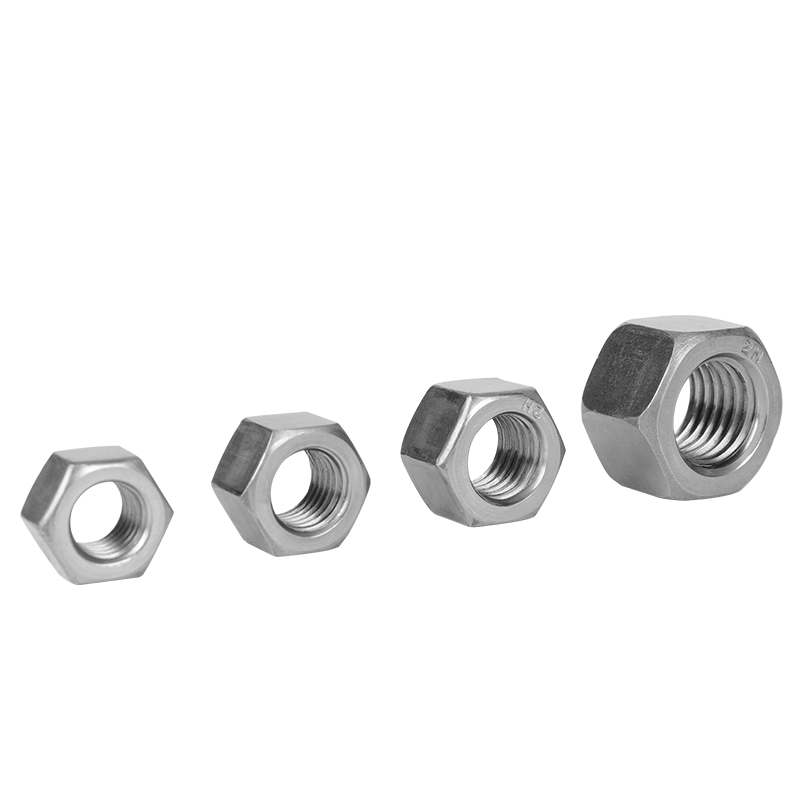

The material of the nut is the core factor that determines its performance. Common Heavy Fasteners Nuts are made of carbon steel, alloy steel, stainless steel, etc. Carbon steel nuts are low in cost and high in strength, and are suitable for general industrial applications; alloy steel nuts significantly improve their strength, toughness and wear resistance by adding different alloy elements, such as chromium, molybdenum, vanadium, etc., and are often used in heavy-load and high-stress environments; stainless steel nuts are widely used in food processing, marine engineering and other fields with strict corrosion protection requirements due to their excellent corrosion resistance. When selecting, check the material certification documents of the product to ensure that the material meets the established standards and avoid quality risks caused by material mismatch.

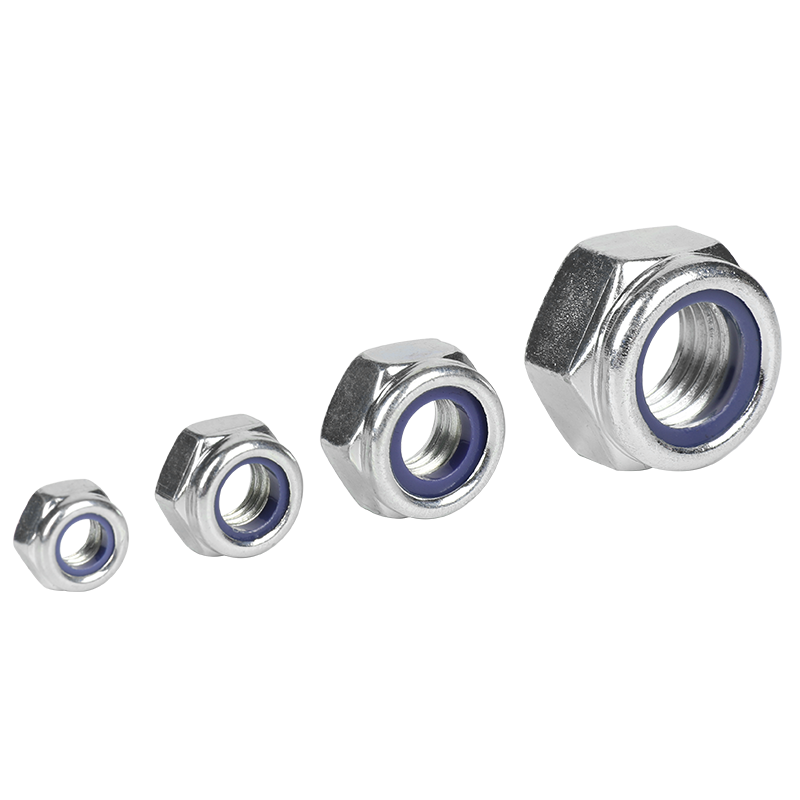

3. Evaluate manufacturing process and precision

High-quality manufacturing process is an important part of ensuring the quality of nuts. Advanced cold heading and hot forging processes can optimize the internal structure of metals and enhance the mechanical properties of nuts. At the same time, high-precision thread processing is crucial to the fastening effect of nuts. The pitch accuracy and tooth angle deviation of the thread directly affect the degree of fit between the nut and the bolt. When purchasing, you can observe the processing marks on the surface of the nut, check the flatness and finish of the thread, or use professional measuring tools to measure key dimensional parameters to determine whether the processing accuracy meets the standards. For example, for nuts used to connect high-precision equipment, the thread accuracy should reach 6H or above.

4. Inspection of product quality and certification

During the procurement process, be sure to ask the supplier to provide product quality inspection reports and relevant certification certificates. The quality inspection report should contain various performance test data of the nut, such as tensile strength, hardness, torque coefficient, etc.; the certification certificate reflects the international or national standards that the product complies with, such as ISO (International Organization for Standardization) certification, EN (European Standard) certification, etc. These documents are strong evidence of product quality and help confirm whether the product meets the requirements of use. In addition, if conditions permit, samples can be randomly inspected and sent to professional testing agencies for comprehensive testing to ensure that the product quality is correct.

ASTMA194/A563 Carbon Steel Heavy Duty Nuts

English

English

Español

Español