Choosing the right metal lock nut to meet different needs requires consideration of multiple factors. Here are some key steps and considerations:

1. Clarify the needs

First, it is necessary to clarify the specific needs of using metal lock nuts, including the working environment, bearing capacity and load, anti-loosening performance, installation space, and cost budget.

2. Consider the working environment

Temperature and humidity: Choose the right material according to the temperature and humidity conditions of the working environment. For example, under extreme temperature conditions, it is necessary to choose high-temperature or low-temperature resistant lock nuts, and consider heat treatment processes to maintain their fastening properties.

Corrosiveness: In chemical, marine and other environments susceptible to chemical corrosion, lock nuts made of corrosion-resistant materials, such as stainless steel, should be selected, and additional protective measures such as coating or plating should be taken.

3. Evaluate bearing capacity and load

Choose the right type according to the force and load size of the lock nut. In heavy machinery such as cranes and excavators, fasteners need to withstand huge loads and impact forces, so lock nuts with high bearing capacity and high impact resistance should be selected.

4. Pay attention to anti-loosening performance

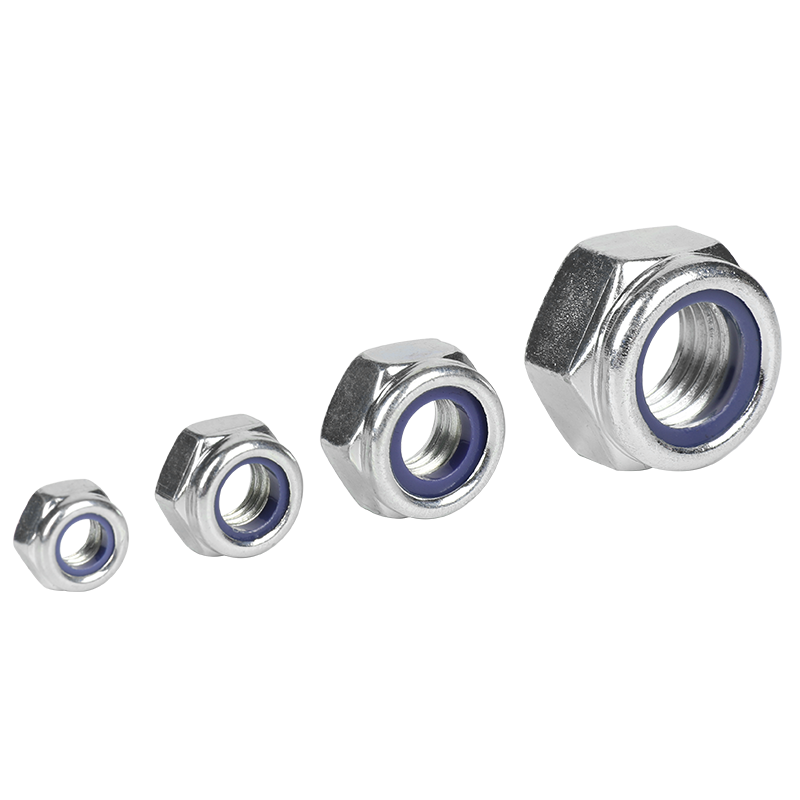

Self-locking characteristics: In a vibrating environment, such as in transportation tools such as railways, cars, and airplanes, ordinary nuts are easy to loosen. Therefore, a locking nut with high elasticity and self-locking characteristics should be selected to effectively prevent loosening caused by vibration.

Anti-loosening design: Consider the internal structure and external design of the locking nut, such as bevels, springs, nylon rings, metal rings, etc. These designs can increase friction or generate additional tension to achieve the locking effect.

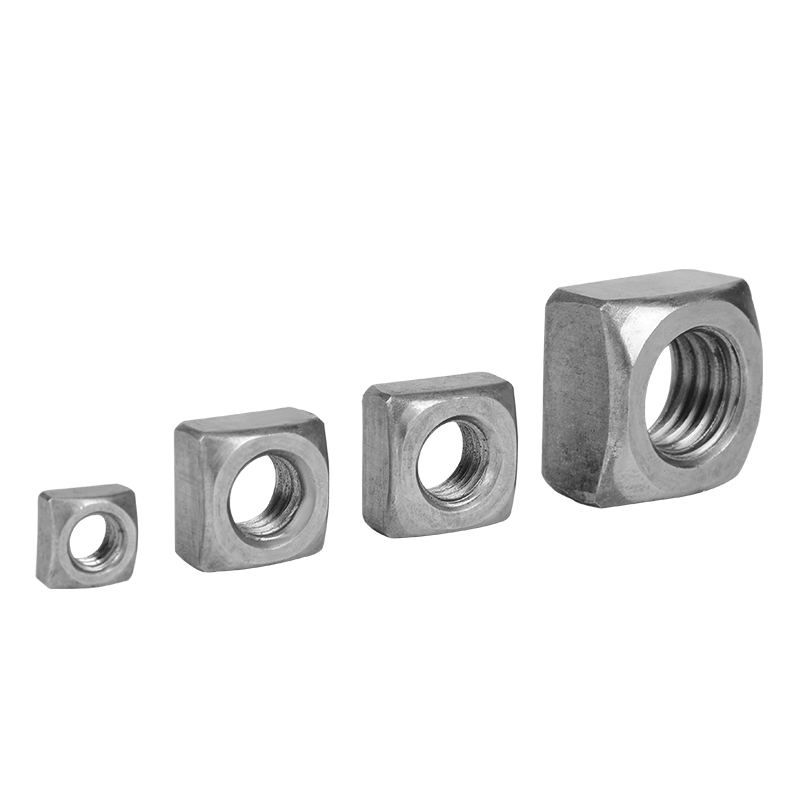

5. Consider the installation space

Choose the type of locking nut with the right size according to the limitations of the installation space to ensure the convenience and effectiveness of the installation. At the same time, pay attention to the installation method of the locking nut, including manual installation, mechanical or hydraulic tool installation, etc., to ensure the correct installation method to obtain a better locking effect.

6. Cost considerations

On the premise of meeting the needs, choose a suitable type of locking nut based on budget and cost considerations. Try to choose products with high cost performance, while considering the service life and maintenance cost of the product.

7. Reference standards and classifications

Standard classification: There are many classifications of locking nuts according to different standards. Common standards include DIN, ANSI and JIS. When choosing, you can choose the locking nut under the appropriate standard classification according to the properties of the workpiece (such as material, grain size, working environment and service life).

Material selection: The materials of locking nuts are usually iron, stainless steel, brass, etc. According to the working environment and service life, choosing the appropriate material can effectively avoid problems such as loosening caused by corrosion of the material itself.

Choosing a suitable metal locking nut requires comprehensive consideration of multiple factors, including working environment, bearing capacity and load, anti-loosening performance, installation space, cost, standard classification and material selection. By carefully evaluating and comparing different options, you can choose the most suitable locking nut to meet different needs.

Non-Metallic Insert Nylon Lock Nuts

English

English

Español

Español