The application practice of metal locking nuts in extreme environments fully demonstrates its unique advantages and broad application prospects. With the continuous advancement of technology and the continuous improvement of processes, metal locking nuts will play an important role in more fields and make greater contributions to the development of the industrial field.

1. Application in high temperature environment

In high temperature environment, ordinary nuts tend to loosen due to the thermal expansion and contraction of materials, thus affecting the normal operation of equipment. Metal locking nuts can maintain stable tightening force at high temperatures through their special design and manufacturing process. For example, some metal locking nuts are made of high-temperature resistant metal alloys, have good thermal stability and creep resistance, and can remain tightened for a long time in high temperature environments. In addition, additional heat transfer measures, such as heat sinks, can be used to help dissipate heat faster and further reduce the impact of thermal expansion and contraction.

2. Application in low temperature environment

In low temperature environment, metal materials are prone to cold brittle changes, resulting in an increased risk of fracture. Metal locking nuts ensure sufficient strength and toughness at low temperatures by selecting materials with good low temperature resistance and conducting corresponding tests and verifications. At the same time, the pre-tightening method is used during the assembly process to ensure that the friction between the bolt and the nut is large enough to avoid loosening.

3. Application in high vibration environment

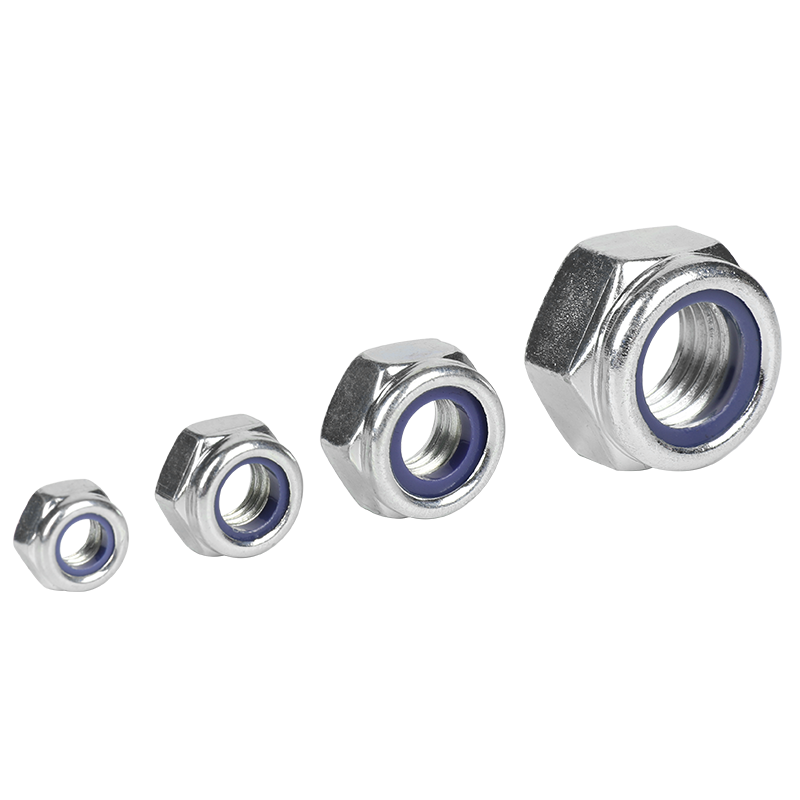

In transportation tools such as railways, cars, and airplanes, continuous vibration can cause ordinary nuts to loosen. Metal locking nuts can maintain tightening force in high vibration environments through their unique locking mechanisms, such as elastic deformation and deformation locking. This locking mechanism enables metal locking nuts to work stably under vibration conditions, ensuring the safety and reliability of equipment.

4. Application in high load environments

In heavy machinery such as cranes and excavators, fasteners need to withstand huge loads and impact forces. Metal locking nuts have been widely used in these occasions due to their high load-bearing capacity and impact resistance. Its special design and manufacturing process enable metal locking nuts to withstand high loads without being easy to loosen, thereby ensuring the stable operation of heavy machinery.

5. Application in chemical corrosion environments

In chemical, marine and other environments susceptible to chemical corrosion, ordinary nuts often fail due to corrosion. Metal lock nuts are made of corrosion-resistant materials, such as stainless steel, alloy steel, etc., and take additional protective measures, such as coating or plating, to improve their corrosion resistance. These measures enable metal lock nuts to remain in a tight state for a long time in a chemically corrosive environment, ensuring the safety and reliability of the equipment.

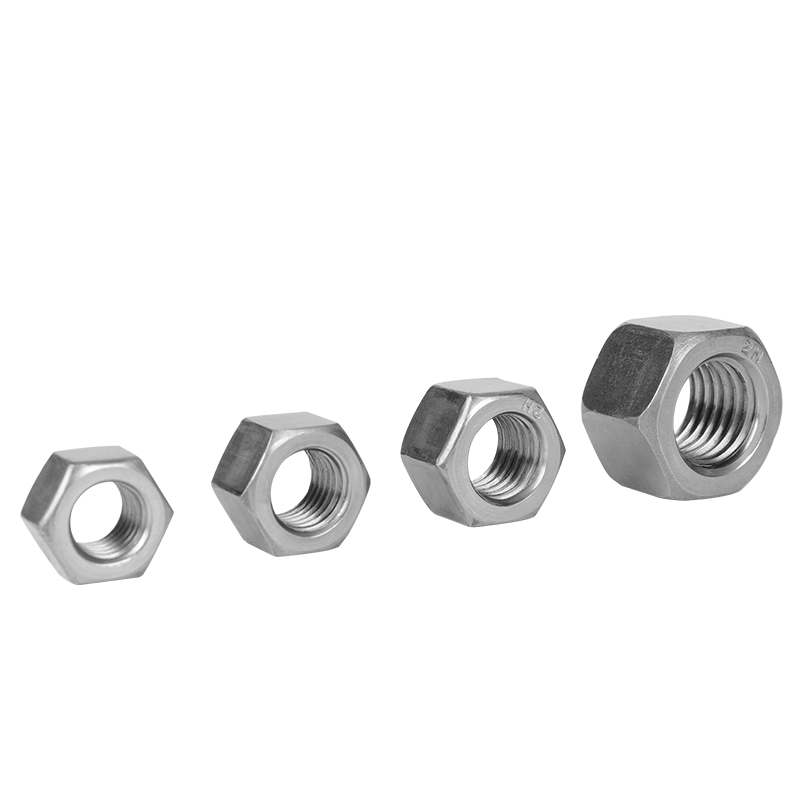

All Metal Lock Nut (v Type)

English

English

Español

Español