|

Standards: |

DIN |

|

Size |

M5-M36 |

|

Surface treatment |

Zinc-plated, black, dacromet |

|

Material |

Carbon steel |

The whole body of all-metal lock nuts is made of metal, and most of them are designed with effective torque mechanisms or keeps (K-Lock). Creates a preload on the bolt that helps keep the nut tight. The k-Lock lock nut is composed of a metal shell and an inner metal insert, the working principle is that when the bolt and nut are tightened, the inner insert will be squeezed to form a sealed ring, thus preventing the bolt and nut from loosening. All metal lock nuts have good corrosion resistance, wear resistance, and high-temperature resistance, which can meet the requirements of different working environments. It also has good tensile strength and impact resistance, which can effectively improve the fastening effect.

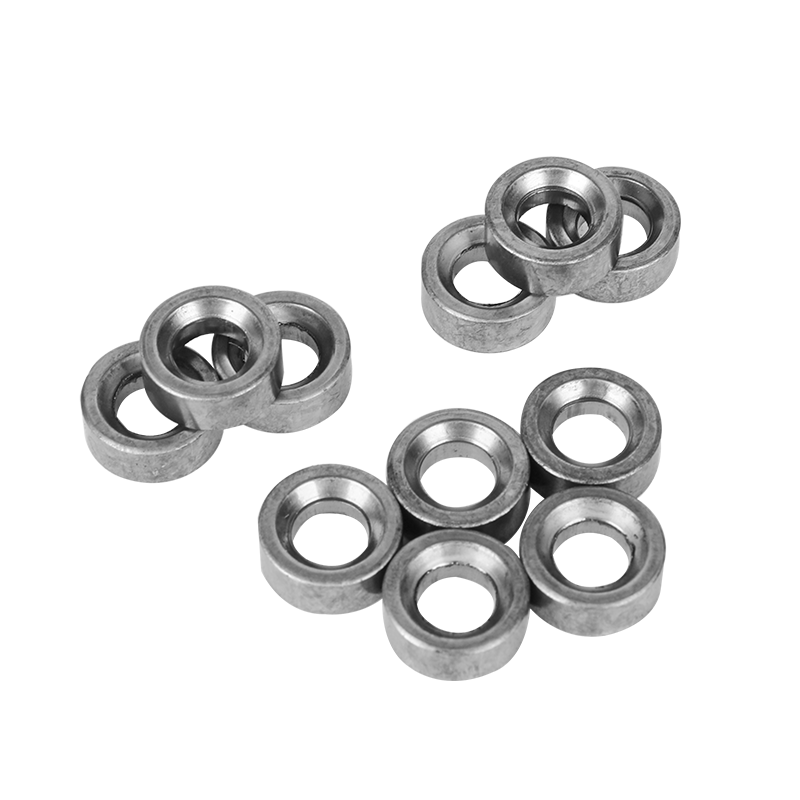

Name: All Metal Lock Nut (V Type)

Standard: Comply with the German industrial standard DIN, ensure the interchangeability and quality consistency of the product, and meet the international general technical requirements.

Size range: From M5 to M36, covering a variety of specifications required from small precision equipment to large mechanical equipment, meeting the installation needs in different scenarios.

Surface treatment:

Zinc plating: Provides excellent anti-corrosion performance, suitable for most indoor and general outdoor environments.

Black treatment: Enhances visual concealment while providing a certain degree of corrosion resistance.

Dacromet: An advanced anti-corrosion coating, especially suitable for harsh environments such as high humidity and high salt spray, with excellent anti-corrosion and anti-rust properties.

Material: Made of carbon steel, it has high strength and hardness, can withstand large tightening and shearing forces, and is suitable for a variety of industrial applications.

Scope and scenario

Automotive industry: In automobile manufacturing, V-type locking nuts are often used to tighten engines, transmission systems, chassis and body structural parts to ensure the safety and reliability of vehicles during driving.

Mechanical equipment: In heavy machinery, engineering machinery, machine tool equipment and other fields, this locking nut is often used to fasten key components due to its excellent locking ability and anti-vibration performance to prevent failures caused by loosening.

Aerospace: In the field of aerospace, the requirements for fasteners are extremely strict. V-type locking nuts are used in the assembly of aircraft, rockets and other equipment due to their high reliability and lightweight design.

Energy industry: Including wind power, nuclear power, hydropower stations, etc., the equipment in these fields often works in high-intensity and high-vibration environments. V-type locking nuts can effectively prevent bolts from loosening and ensure the safe operation of equipment.

Rail transit: In rail transit systems such as railways and subways, it is used for track fixing, vehicle component connection, etc. to ensure smooth and safe train travel.

Construction field: In the construction of infrastructure such as steel structure buildings and bridges, V-type locking nuts also play an important role to enhance the stability and durability of the structure.

Production Experience

Technical Staff

Annual Output

Follow Our News

Provide you with the latest enterprise and industry news.