In various industries, the use of non-metal insert nylon lock nuts has become increasingly prevalent due to their unique advantages over traditional metal nuts. These nuts find extensive applications across electronics, automotive, and mechanical manufacturing sectors.

Within the realm of electronics, where precision and insulation are paramount, non-metal insert nylon lock nuts serve as essential components. These nuts are commonly employed for securing circuit boards and other electronic components. Their lightweight nature, coupled with excellent insulation properties, makes them ideal for electronic device manufacturing. Unlike metal nuts, which may conduct electricity and pose a risk of short circuits, nylon lock nuts offer superior electrical insulation, ensuring the safety and reliability of electronic devices. Additionally, their corrosion resistance further enhances their suitability for use in electronic applications, particularly in environments where exposure to moisture or chemicals is a concern.

The automotive industry relies heavily on non-metal insert nylon lock nuts for various assembly applications. These nuts are utilized in securing structural components, interior fittings, and electrical components within vehicles. Their lightweight construction contributes to overall weight reduction, a crucial factor in modern automotive design aimed at improving fuel efficiency and performance. Moreover, nylon lock nuts exhibit excellent resistance to corrosion, a vital attribute in automotive applications exposed to harsh environmental conditions such as road salt and moisture. Additionally, their ability to dampen vibrations helps minimize noise and enhance driving comfort, making them an integral part of automotive engineering.

In mechanical manufacturing,

non-metal insert nylon lock nuts play a vital role in fastening machine components and reducing assembly complexities. Their versatility and durability make them well-suited for a wide range of applications, from industrial machinery to consumer products. These nuts offer significant advantages over traditional metal nuts, including resistance to corrosion, reduced weight, and the ability to operate without the need for lubrication. Furthermore, their impact-resistant properties contribute to improved performance and longevity in demanding operating environments. Manufacturers benefit from the ease of assembly and reduced maintenance requirements associated with nylon lock nuts, ultimately enhancing overall operational efficiency.

Non-metal insert nylon lock nuts represent a versatile and reliable fastening solution across electronics, automotive, and mechanical manufacturing industries. Their lightweight construction, superior insulation, corrosion resistance, and vibration-dampening properties make them indispensable components in various applications. As industries continue to prioritize efficiency, safety, and performance, the demand for these innovative fasteners is expected to grow, further solidifying their position as indispensable components in modern manufacturing processes.

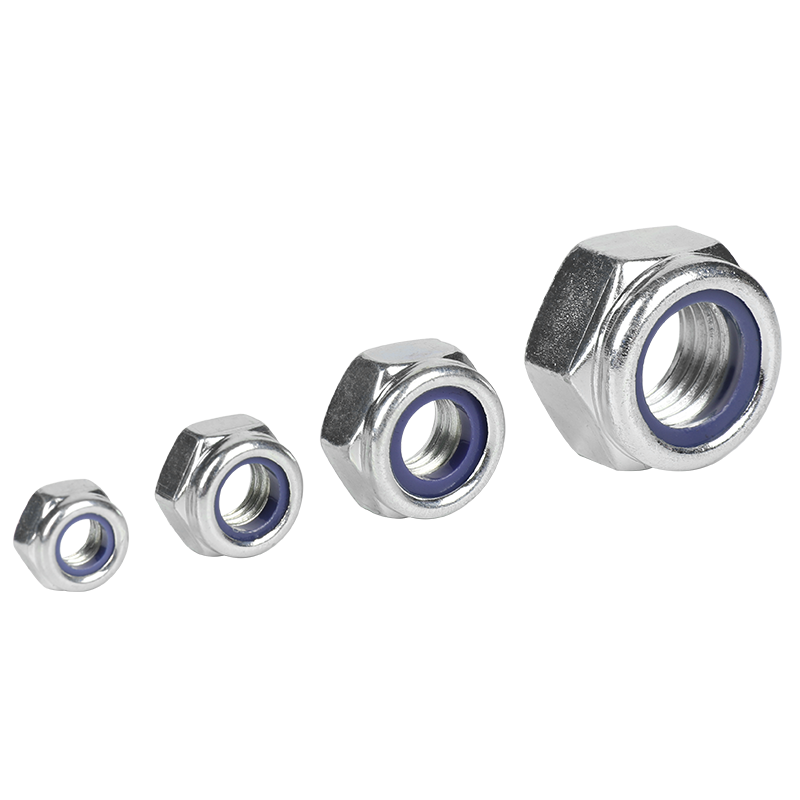

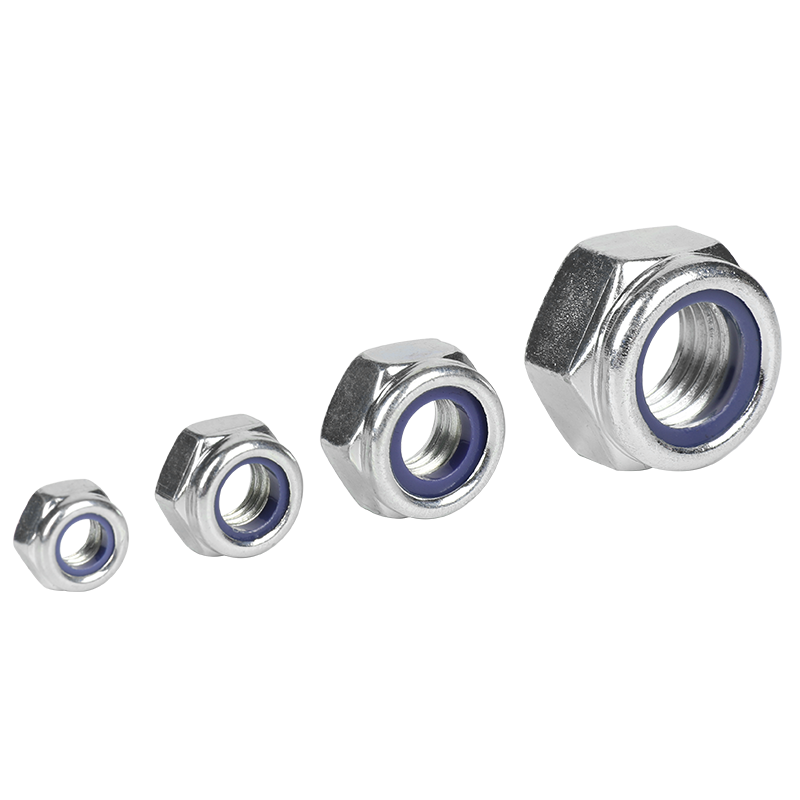

Non-Metallic Insert Nylon Lock Nuts

Non-Metallic Insert Nylon Lock Nuts